NextGel Porcelain Paver Jointing Sand

Now available to order.

A faster & cleaner solution for grouting porcelain pavers. Specifically designed for your porcelain projects with Ultra-Clean Technology.

Coverage power depends on paver type and joint width.

Please refer to this product's technical data sheet for complete information. Whenever the information presented on this website differs from the one contained in the official technical data sheet, the latter always prevails.

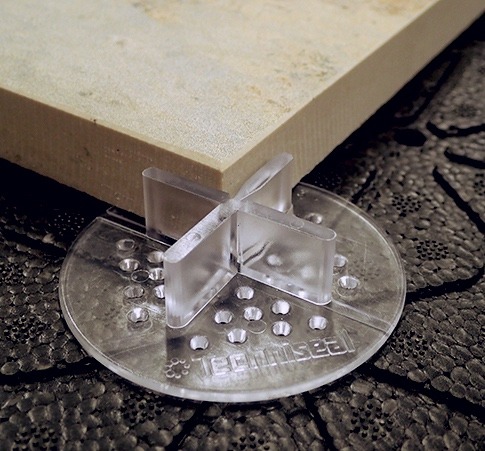

NextGel™ Porcelain Paver Jointing Sand is an innovative alternative to mortar for installing Porcelain Pavers. It is also suitable for granite, marble, travertine and other natural stones. The Ultra-Clean Technology ensures a Haze and Dust-Free environment during installation. NextGel™ Porcelain Paver Jointing Sand is a state-of-the-art mix of graded sand and binder that smoothly flows down joints, allowing for a fast and effective installation of pavers or slabs with false, narrow or wide joints. Its fast-wetting proprietary formula, colour consistency, and efflorescence-free properties make it the best solution for your next porcelain pavers project, available in a convenient 25 lb bag.

Techniseal® NextGel™ Porcelain Paver Jointing Sand is manufactured with revolutionary technologies. NextGel™ radically transforms and improves the properties and behaviour of jointing sand, resulting in the first-ever true “no dust”, “no haze” and “no waste” jointing sand for a fast, clean, durable, and profitable installation. Additionally, the Ultra-Clean Technology brings that innovation a step further to create virtually dust-free jointing products.