FAQ | Polymeric Jointing Sand

what is polymeric sand?

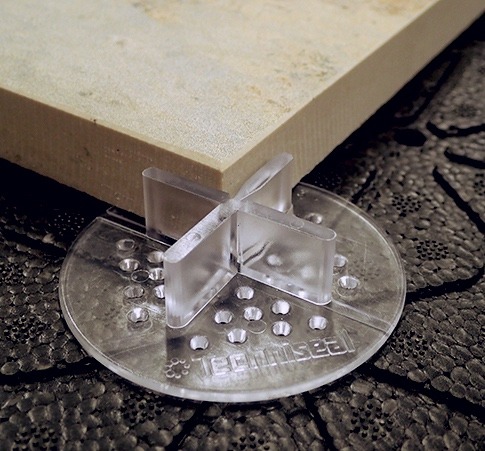

Polymeric sand is a mixture of fine sands and small additive particles called "polymers". It is used to obtain firm and durable joints when installing pavement materials such as concrete pavers and slabs, natural stone, and porcelain tiles.

in jointing sands, what are polymers and what purpose do they serve?

Polymers are small additive particles that are mixed with sand grains during the manufacturing of polymeric jointing sand. When exposed to water or moisture, these are activated and act as a powerful binding agent that provides firm and highly-resistant joints to hardscape installations.

when did polymeric sand first become available?

Techniseal was the first manufacturer to offer polymeric sand technology at the turn of the 2000s. More than 20 years after the launch of its first jointing sand, Techniseal still remains the best-known and most trusted manufacturer in the industry, thanks in part to the launch of its revolutionary Nextgel formula in 2015.

what is the nextgel technology?

Exclusive to Techniseal, the Nextgel technology is a cutting-edge manufacturing process that drastically improves the base properties of polymeric sand.

Jointing sands that benefit from the Nextgel technology are easier to spread, faster to activate and much cleaner to install, forming no dust or haze. Overall, this groundbreaking technology makes the jointing of concrete pavers way more convenient for the installer and his customer.

The Nextgel technology is used in the manufacturing of Techniseal’s high performance HP Nextgel jointing sand since 2015. Starting 2019, this process was also utilized in the production of SmartSand, a next generation jointing sand that was launched as an upgrade to RG+ for paver installations carried out in residential areas.

what are the main advantages of polymeric sand?

The use of polymeric sand for concrete paver installations has several advantages, including:

- Optimal joint stabilization

- Avoids weed growth and ant infestation

- Added resistance against natural erosion

- Quick & simple application

- A more aesthetic appearance of paver joints

how to choose the right polymeric sand for my paver installations?

Several types (and grades) of polymeric sand are available on the market. Techniseal is the only manufacturer to offer a "One-Sand-Fits-All" product suitable for all types of installations in any types of environments.

Our HP Nextgel Polymeric Jointing Sand offers unsurpassed joint stabilization, even in high humidity areas, sloping terrain, and high vehicular traffic regions.

For smaller-duty installations, Techniseal offers paver experts a cost-effective alternative. Even though SmartSand offers lesser jointing performances, this poly sand is more than suitable for residential installations that are not subjected to heavy vehicular traffic.

how many colors of polymeric sand does techniseal currently offer?

Overall, Techniseal's polymeric sands are offered in more than twenty beautiful colors. This makes us the sand manufacturer with the greatest number of colors to offer to hardscape professionals.

Obviously, the availability of the different colors depends on the type of sand chosen and the geographical region in which you are located.

how long does it take after the last rain to install polymer sand?

In general, it is recommended to wait at least 24 hours after any significant rainfall to proceed with the installation of polymeric sand. Understandably, it is not recommended to lay jointing sand in the rain, or when precipitation are expected in the hours following your work.

how long after installing polymeric sand can pavers be sealed?

Traditionally, concrete paver manufacturers have recommended waiting at least 90 days after polymeric sand installation to apply a protective sealant to a paver surface. Nowadays, a 30 day delay is sufficient to allow the evaporation of any remaining natural efflorescence contained in the pavers. Just remember that thorough cleaning and proper surface preparation should always precede the application of any protective sealant.

how do I know if my polymeric sand has been sufficiently wetted ?

Proper wetting of the polymeric sand is essential for optimal stabilization of paver joints. To ensure that this important step is done right, we recommend that you generously water the sand until a thin whitish layer starts emanating from the paver joints. You can then stop watering this section of the surface and move on to the next one.

STILL GOT QUESTIONS ABOUT POLYMERIC SAND?

Our technical support team is there to give you all the answers!

Simply reach out to them by dialing 1 800 465 7325 or by sending them an email at service@techniseal.com

You can also fill-out our website contact form.